Slaughter Line

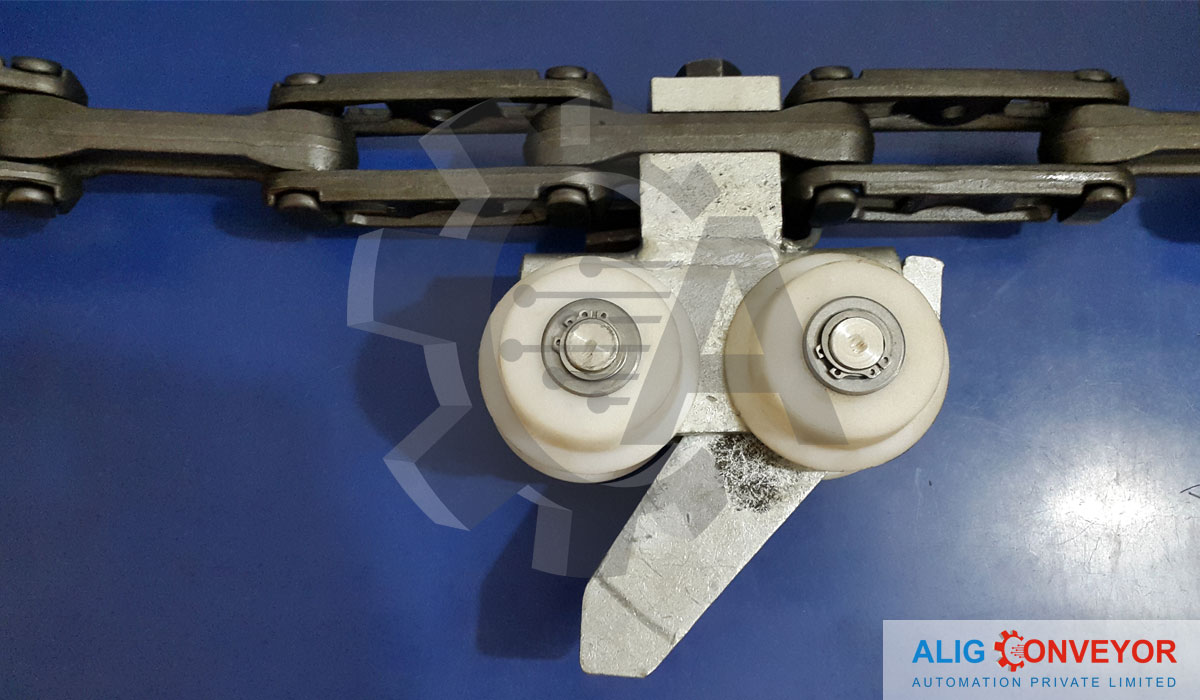

An overhead conveyor system for slaughtered ANIMALS comprises a track supported above the floor, a number of suspension hooks which are movable along the track and are positioned one after the other, each bracket, a continuous chain or cable to which each suspension hook is connected and means for moving the chain or cable with the suspension hooks connected thereto. Each suspension hook is provided with a bar which connects the brackets, a disc connected to the top section of the bar, a rotation bush of square cross section which forms part of the bar or is connected thereto and has a twisted shape in the longitudinal direction, and a guide bush which is arranged around the said bar and allows both a limited longitudinal movement and a rotary movement of the bar. Furthermore, each suspension hook has a hinge pin which is joined to the guide bush and which always extends in the direction of transport and is suspended using trolleys having wheels which engage on the track.

Brief Description

- a bar which connects the said brackets,

- a disc connected to the top section of the bar,

- a rotation bush of square cross-section which forms part of the bar or is connected thereto and has a twisted shape in the longitudinal direction,

- a guide bush which is arranged around the said bar and allows both a limited longitudinal movement and a rotary movement of the bar,

- a hinge pin which is joined to the guide bush and which always extends in the direction of transport of the suspension hooks and is mounted on trolleys