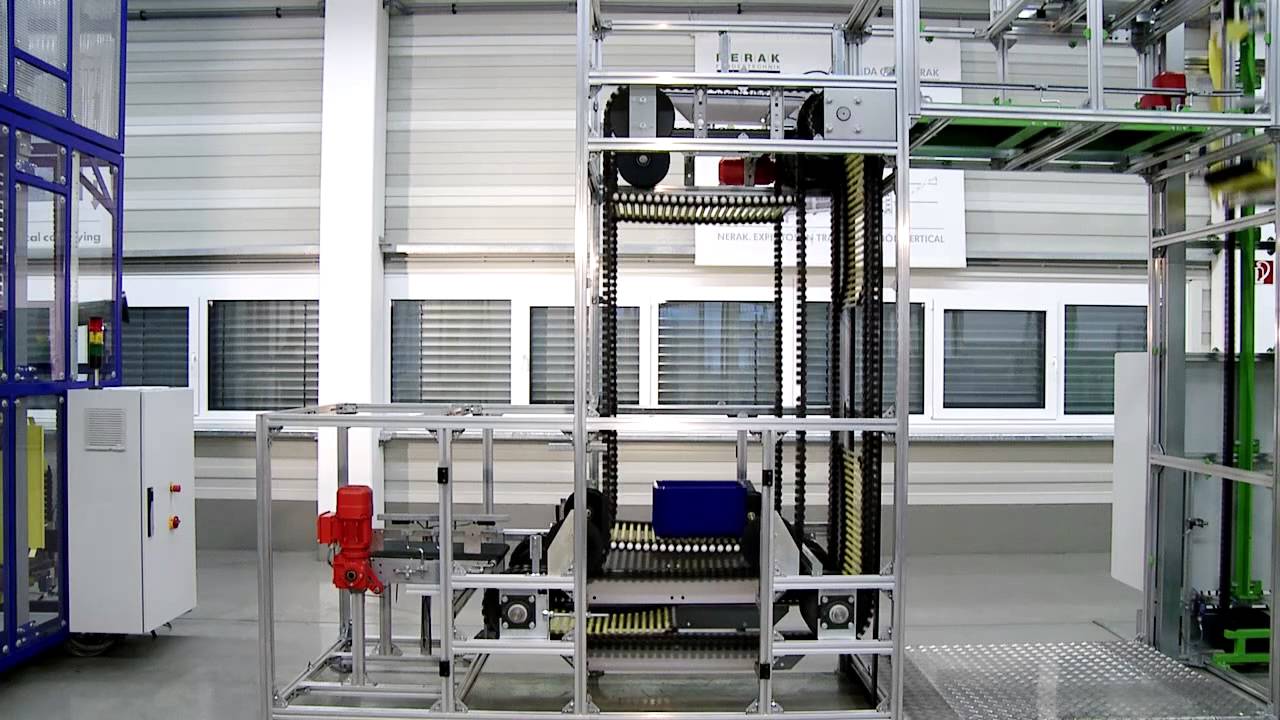

Vertical Chain Conveyors

Opposed-shelf type that has two or more vertical elevating conveying units opposed to each other. Each unit consists of one or more endless chains whose adjacent facing runs operate in parallel paths. Thus, each pair of opposing shelves or brackets receive objects (usually dish trays) and deliver them to any number of elevations.

Requirement

- Moving heavy products from one level of height to another vertically.

- Moving product through high temperature zones (e.g. ovens) where other conveyor types may not be suitable

- Moving in either stepped or single modes (i.e. the chain stops and starts each time to move a product to the end of the chain using a sensor)

- Changing the speed is necessary. When fitted with a VFD (variable frequency drive), a chain conveyor is a simple conveyor to adjust the speed on

Advantages

The possibility of moving wide heavy materials

- Thanks to the gap between the individual branches, it is possible to convey even the materials that reach under the upper branch of the conveyor

- High load-carrying capacity

- The possibility of replacing individual links of the chain instead of replacing the entire chain

- Fast assembly and delivery

- The number of branches can be selected depending on the nature of the material being moved

- Possibility of managing special requirements of the customers, such as the use of a different chain type, chain with carriers, etc.